These connectors are to replace the 14-pin connector on the 10-foot interconnect contactor cord. Optimizes contrast and clarity in welding and light states. Conventional mode for MIG welding. For example; if wire speed is set to 400 in/min., a welding procedure arc voltage of at least 17V would be required to obtain the 400 in/min.

Available on Dimension NT 450, XMT 350, Trailblazer Series, and PRO 300. This means your parameters can vary slightly.  A weld made between or upon overlapping members in which coalescence may start and occur on the faying surfaces or may proceed from the surface of one member. Permits quick reset at gun rather than at machine. A joint between two members located approximately at right angles to each other in

A specially tuned muffler and a longer exhaust pipe improve the balance of high- and low-noise frequencies. Lincoln Electric process designed to increase stability and travel speeds, while reducing spatter and internal porosity on Zinc coated materials. If power source has a Miller 5-pin receptacle, order 039273 and 039685. The length of weld throughout which the correctly proportioned cross section exists. Nonmetallic solid material entrapped in weld metal or between weld metal and base metal. Automatically adjusts the amount of current required to clear a short. NDT involves the testing of welds without destroying the welds or parts. This voltage may be legal, and in normal (dry) conditions may be quite safe. S.G.K. Integrated cooler runs only when needed on Syncrowave 250 DX and 350 LX.

A weld made between or upon overlapping members in which coalescence may start and occur on the faying surfaces or may proceed from the surface of one member. Permits quick reset at gun rather than at machine. A joint between two members located approximately at right angles to each other in

A specially tuned muffler and a longer exhaust pipe improve the balance of high- and low-noise frequencies. Lincoln Electric process designed to increase stability and travel speeds, while reducing spatter and internal porosity on Zinc coated materials. If power source has a Miller 5-pin receptacle, order 039273 and 039685. The length of weld throughout which the correctly proportioned cross section exists. Nonmetallic solid material entrapped in weld metal or between weld metal and base metal. Automatically adjusts the amount of current required to clear a short. NDT involves the testing of welds without destroying the welds or parts. This voltage may be legal, and in normal (dry) conditions may be quite safe. S.G.K. Integrated cooler runs only when needed on Syncrowave 250 DX and 350 LX.

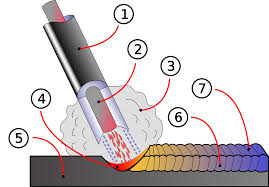

An alkaline aqueous solution of a hydroxide such as KOH is used for metals such as zinc and iron with their discharge products being hydroxides or oxides. A stratum of weld metal or surfacing material. A surface of the base metal which will be melted during welding. The materials, detailed methods and practices employed in the welding of a particular joint. welding, and between all layers and passes. Starts the arc at any amperage without contaminating the weld with tungsten. Peter Sonnenfeld, in Encyclopedia of Physical Science and Technology (Third Edition), 2003. The area of the weld metal as measured on the cross section of a weld. The capacity is calculated based on the space of metal only. Indicator lights will also signal when output voltage during welding is above or below 30 volts DC. Common lubricants are metallic soaps such as stearates of zinc, iron, and barium. OM-245892J Sept 2017 Dedicated gun designed for the 74 MPa Plus feeder to complete a push-pull system for optimized aluminum feeding and welding performance. Oxygen is essentially free from any restriction as regards resources and environmental problems. Miller Blue Star 185 Gas Engine-Driven Welder/AC Generator 907664, Index No. damp, wet, caustic, salty conditions, high or confined space) working conditions, and an electric shock in these situations can be hazardous to the operator including dangers due to ventricular fibrillation, falling from heights, and inability to escape the power source when in confined spaces, not to mention the serious physical injuries sustained as a secondary result of an electric shock. A patent pending adjustable baffling system inside the helmet directs air away from eyes to keep them from getting dry. At that point, all the liquid metal willhave turned to solid. Some gauges are multipurpose or single purpose. It also enhances simple position welding making the job easier. These connectors are to replace the 14-pin connector on the 10-foot interconnect contactor cord. On/Off Magnets for BRR, Bent Rigid Rail Section, for circumferential applications, can be ordered either as a complete ring or as individual sections, Split Tube Carriage for bent aluminum rigid rail applications, can be placed anywhere along the track and easily adjusts to various work diameters, Automatic Height Control System for WPD-1100 Linear Weaver, Automatic Height Control for WPD-2100 Pendulum Weaver, Spacer Bar, use with ARM-2010 & ARM-2010-HH only, for hi-flex rail, Rail, Hi-Flex, with 8 rare earth on/off magnets, Hi-Flex Magnet with release for hi-flex rail, MDS Hi-Flex Programmable Stitch Kit, 120VAC, MDS Hi-Flex Programmable Stitch Kit, 240VAC, MDS FMD-4404 MDS Hi-Flex Programmable Stitch Kit, 42VAC, MDS Straight Line Programmable Shape Plasma Cutting/Welding Kit, 120VAC, MDS Straight Line Programmable Shape Plasma Cutting/Welding Kit, 240VAC, MDS Straight Line Programmable Shape Plasma Cutting/Welding Kit, 42VAC, MDS Hi-Flex Programmable Shape Oxy-Fuel Cutting Kit, 120VA, MDS Hi-Flex Programmable Shape Oxy-Fuel Cutting Kit, 240VAC, MDS Hi-Flex Programmable Shape Oxy-Fuel Cutting Kit, 42VAC, Bug-O MDS Modular Drive System, includes Master Drive Unit MPD-1000 (120VAC), optional Control Modules (for programmable shape cutting or welding, straight-line cutting and/or welding, straightline gouging, programmable stitch welding, as well as weave capability), optional aluminum rails (rigid/bent rigid/semi-flex/hi-flex), carriages (standard/bent/hi-flex), various attachments and supports, LIT-MDS-BRO-0319, Master Drive Unit 120VAC,50/60Hz, runs from 2-120 in/min (51-3048 mm/min) with a vertical load capacity of 60 lbs (27 kg) and a horizontal load capacity of 100 lbs (45 kg), Master Drive Unit 240VAC,50/60Hz, runs from 2-120 in/min (51-3048 mm/min) with a vertical load capacity of 60 lbs (27 kg) and a horizontal load capacity of 100 lbs (45 kg), Master Drive Unit 42VAC,50/60Hz, runs from 2-120 in/min (51-3048 mm/min) with a vertical load capacity of 60 lbs (27 kg) and a horizontal load capacity of 100 lbs (45 kg), Bug-O MDS Weaver Control Modules for MDS Systems, Operates the Pendulum or Linear Weaver, and the Master Drive Unit. This is the case with the shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux cored arc welding (FCAW) and SAW processes. The electrode is of a similar material to the parent material and by melting both together it provides the weld (or joint) with a reinforcing filler material. A block sequence during which successive blocks are completed progressively along the joint, either from one end to the other or from the center of the joint toward either end. pole and the electrode is the negative pole of the welding arc. welding. A device used in arc welding circuits for the purpose of minimizing irregularities in the flow of welding current. var theDate = new Date()

(This process has sometimes been called TIG welding, a nonpreferred term. Found on the Deltaweld 350 System. A Miller Technology Exclusive. Miller Millermatic 350P All-In-One MIG Welder 907300, All-In-one package with steel and aluminum MIG and pulsed MIG processes, Constant speed motor with Industrial 4 drive roll system, Compatible with MIG, spool and push-pull guns, 4000 series & 5000 series aluminum wire, optional push pull accessory, Miller Millermatic 350P Aluminum 907474 Legacy, MIller Millermatic 350P Aluminum w/15 ft. XR-Aluma-Pro 951868 Legacy, Miller Millermatic 350P Aluminum w/25 ft. XR-Aluma-Pro 951869 Legacy, Miller Millermatic 350P Aluminum w/25 ft. XR-Aluma-Pro Lite 951454 Legacy, Miller Millermatic 350P Aluminum w/25 ft. XR-Pistol-Pro 951453 Legacy. Kubota D-1105 BG 13.5 hp (8 kW generator), 4-1250 watt metal halide fixtures, initial output of 150,000 lumens per lamp, Domestic Shipping Weight: Light Fixtures: 15 lbs. When a load of less than 200 ohms resistance is applied to the output of the welding machine, the VRD will sense this resistance and adjust the welder to full output so that the welding arc can be established and welding commenced. A kilowatt is simply 1,000 watts, which is a measure of power. during operation, Thermally protected 1/4 hp motor guards against overheating, Efficient fin-and-tube heat exchanger, Brass-body positive-displacement rotary vane pump provides consistent coolant flow and pressure rating with long pump-life expectancy, Miller Coolmate 4 Water Cooler 120V, 50/60 Hz 042288, Index No. Shuts down output when the MIG contact tip is shorted to the work, on the Millermatic 135 and 175. A variation of the gas metal arc welding process in which the current is pulsed. That surface of a member included in the groove. When the pipe was volumetrically inspected using SA-655, a lamination was discovered, running around the full circumference. This terms designates reject ability.

Designed for smaller capacity applications. Triangle, circle, and square symbols correspond to the valence changes of 1, 2 and 3, respectively. A high speed, diesel engine-driven welder/generator capable of dual or single operator DC multi-purpose welding. A coarse grain structure will result in a material with less toughness than a fine grained material. The liquid state of a weld prior to solidification as weld metal. That mating surface of a member which is in contact or in close proximity with another member to which it is to be joined. 12.22A. A specified temperature that the base metal must attain in the welding, brazing soldering, thermal spraying, or cutting area immediately before these operations are

When switched to the LO range position, the constant wire feed speed (CV Wire Feed Mode) is set on the inside (white) dial range calibrated for 50 to 350 in/min. The molten weld pool is

Any weld designed primarily to provide a specific degree of tightness against leakage. External shielding may or may not be used. In order to produce an outstanding weld performance on a variety of electrodes (rutile, basic or cellulose), the arc force can be finely adjusted with a

A weld made to attach a piece or pieces to a weldment for temporary use in handling, shipping, or working on the weldment. An arc welding process which produces coalescence of metals by heating them with an arc between a carbon electrode and the work. In a curved weld, it shall be measured along the axis of the weld. Red-D-Arc FX360XL CC/CV Multiprocess Welder K4275-1, Red-D-Arc ES270ie (CE) K???? Found on T94, Digital Infinity, Digital Elite and

A method of determining particle size distribution, usually expressed as the weight percentage retained upon each of a series of standard screens of decreasing mesh size. Compatible with Magnum PRO Push Pull Guns. The analyzer uses a combustion process to oxidize substances into simple compounds that are then quantified by thermal conductivity detection or infrared spectroscopy. Can also be used with constant voltage power sources or DC engine drives supplying 115 volts. Example are inert gases, combusted fuel gases, hydrogen

Prime power ratings can be defined as having an unlimited run time, or essentially a generator that will be used as a primary power source and not just for standby or backup power. Available on these machines: Miller Advanced Active Field Control Technology. Another way of putting this is that the "heat sink" effect of the base metal increases with increasing thickness. There is however an "upper limit" above which thedecreased dilution effect tends to stop playing such a big role. The standard types of groove welds are double-bevel-groove weld, double-flare-bevel-groove weld, double-flare-V-groove weld, double-J-groove weld, double-U-groove weld, double-V-groove weld

H&S Tool Model AFC-16 Split-Frame Clamshell, Part Number AFC16Dk-R. Nominal Pipe Size 8-16 inches, Tripper 4 inch, Extension Pad - , 1, & 2 inches, Tool Slide 3-inch, Air Motor 4800, Includes complete machine assembly with DEFENDER kit, extension pads, tool slide assembly, air motor, tool kit, Clamshell box, and operating manual.

There were two primary reasons to develop Lift TIG. the fillet weld cross section. It is sometimes called an induction generator. For example, if 24 volts is set on the welding power source, as a result of electrical resistance through the cables, only 20 volts may actually be available at the wire feeder. As an example, two 12mm thick plates being welded in a butt configuration will have a material thickness of 12mm. Shindaiwa's Utra-Quiet technology significantly reduces generator sound levels by means of air dams and insulated panels re-direct cooling air, doubling length-of-travel to minimize airflow noise without the need for power-robbing auxiliary fans. ID 5 in. The welding position used to weld from the upper side of the joint: the face of the

Variation of hydrogen concentration as function of charging time. It is for this reason that the automotive industry has converted a large number of parts to P/M. A Miller Technology Exclusive. Every welding code will deal with the base metal thickness essential variable differently, so there is no single qualified range. during

Learn more about the, An arc welding process which produces coalescence of metals by heating them with an arc or arcs between a bare metal electrode or electrodes and the work.

Red-D-Arc Classic 300D K1643-9SPL1 Diesel Engine Welder, Red-D-Arc D200K 2+6 Diesel Engine Welder Legacy, Red-D-Arc D300K 3+10 CC/CV Diesel Engine Welder Legacy, Red-D-Arc D300K 3+3 AirPak Diesel Engine Welder/Compressor and Plasma Cutter Legacy, Kubota diesel, Swan SVU-202 11cfm @ 90psi compressor, Miller Spectrum Plus plasma cutter, Red-D-Arc D300K 3+3 K1687-1 Diesel Engine Welder, Red-D-Arc D300K 3+3 SE K3265-1 Diesel Engine Welder, Red-D-Arc D302K 3+10 500498 Diesel Engine Welder, Red-D-Arc D302K 3+12 500498001 Diesel Engine Welder, Red-D-Arc D325K 3+12 907755006 Diesel Engine Welder, Red-D-Arc D400K 4+3 K1687-1 Diesel Engine Welder International, Red-D-Arc D402K 4+12 500498002 CC/CV CE Diesel Engine Welder, Red-D-Arc D402K 4+12 500498021 CC/CV CE Diesel Engine Welder, Red-D-Arc D500K 5+3 K1689-1 code 10569 Diesel Engine Welder Legacy, Kubota F2803BG1-RDA-1 5 cylinder, 41 HP @ 1800 RPM

AY/7.2, Industrial 3-gallon cooler designed for water-cooled torches rated

A composite filler metal electrode consisting of a core of a bare electrode or metal cored electrode to which a covering sufficient to provide a slag layer on the weld metal has been applied.

Intuitive push-and-turn digital controls and seven-inch, full color display guides users through the process to make setup and operation intuitive and simple. The VRD function can be disabled or enabled via dip switches on the user interface P.C. Used in TIG welding for arc ignition and stabilization. A small crack-like discontinuity with only slight separation (opening displacement) of the fracture surfaces. The buttering provides a suitable transition weld deposit for subsequent completion of the butt weld. 2. (355.6 mm), Travel: 4.5 in. These welding machines have limited maximum short circuit current. Automatically adjusts engine speed to a corresponding rpm level so the engine never works harder than necessary. As the distance increases from the device, more torque is applied to the positioner. Spool guns, consisting of a gun with a pistol grip and a 4-inch diameter wire spool mounted on the back end, provide mobility. (1 Inch). These wires are very voltage sensitive and generally require the fine-tuning capabilities of a CV machine. Certification in writing that a welder has produced welds meeting prescribed standards. The theoretical specific and volumetric energy density of fuel cells with a 35-MPa-H2 pressure vessel can be 3.7Whg1 and 1.0Whcm3, respectively, so they are gravimetrically very promising but less attractive in terms of the volume. is fused to the base metal throughout its total thickness. The Australian structural steel code AS 1554.1 limits the lower thickness to half the coupon thickness. Operates on 115-volt power and designed primarily for constant-current DC power sources. The act of adding a separate piece or pieces of material in a joint before or during

high temperature service. Internal inverter power source circuit that automatically links the power source to the primary voltage being applied (230 V or 460 V), without the need for manually linking primary voltage terminals.

A modified spray transfer process that produces no spatter, because the wire does not touch the weld puddle. A crack in the weld or heat-affected zone occurring at the root of a weld. A spot weld made by an arc welding process. Based off Lincoln Electrics patented STT process, AC-STT combines the proven spatter reducing technology of the STT waveform with the balanced heat-input characteristics of AC GMAW, producing an advanced short circuit process optimized specifically for thin-gauge materials. As shown in Fig. A Miller Technology Exclusive. 400A 40V @ 100% duty cycle, 98V max OCV

The faster this process occurs, the more "grains" there are in the solidified weld. A test specimen composed wholly of base-metal. That portion of the groove face adjacent to the root of the joint. MIG (Millermatic 211), Multiprocess (Multimatic 200/215/220 AC/DC), Stick (Thunderbolt 160), TIG (Diversion, Syncrowave 210), Engine Drives (Fusion), Plasma Cutters (Spectrum 375/625). Base metals of alloy 718 were cut into approximately 20mm10mm2mm and charged in electrochemical cell containing 0.1M H2SO4. Fig. Copyright

Theoretical voltage and gravimetric capacity of metal/air batteries. The shape and dimensions of a joint in cross section prior to welding. Any residue or ash left by the lubricant impedes the particle sintering, thus resulting in parts with poor mechanical properties. A Miller Technology Exclusive. (Also called short circuiting transfer.) A non-filler material electrode used in arc welding or cutting, consisting of a carbon or graphite rod, which may be coated with copper or other coatings. A lens which does not incorporate correction. An optical material which protects the eyes against excessive ultraviolet, infrared, and visible radiation. to 10,000 lbs: Mini Pipers, Piper 3, and Super Piper. Developed by Lincoln Electric.

When welding with the dip transfer mode of GMAW, a lot of the heat goes into resistance heating of the wire, and not into the arc. A method of electroslag welding in which filler metal is supplied by an electrode and its guiding member. During fusion welding, the weld metal and Heat Affected Zone (HAZ) of the base metal next to the weld,undergo phase transformations and other changes to the microstructure. A filler metal electrode consisting of a single metal or alloy that has been produced

A test specimen

A device used for controlling the cast of coiled wire to enable it to be easily fed in to the gun. Many engineering firms, construction companies and building codes no longer allow flux cored welding (FCAW) with a CC power source. Reduces OCV on several Maxstar and Dynasty models when power source is not in use, eliminating need for add-on voltage reducers. For Spoolmatic guns. Note: Bare electrodes and composite electrodes as defined under arc welding electrode are used for electroslag welding. A destructive testing method where the sections of a weld are polished, etched and examined under a microscope for defects.

Minor amounts of ingredients providing such functions as arc stabilization and fluxing of oxides may be included. Turning rolls manufactured by Pandjiris with a capacity range of 8,000 to 15,000 lbs. The organic fraction of the chloride complex turns into liquid petroleum that appears in fluid inclusions or in mine seeps. The kilogram or kilogramme (SI unit symbol: kg) is the base unit of mass in the International System of Units (SI). A tonne is called a metric ton in the United States to help differentiate between metric and imperial. The travel angle when the electrode is pointing backward. A Miller Technology Exclusive. This gives Micro-Start TIG very stable low current welding and provides it with the ability to eliminate erratic high frequency and weld thin materials in a consistent, high quality manner. Developments have shown that the properties of the premix can be enhanced through the addition of binders. Kilowatts are found by taking volts times amps divided by 1,000 and taking into account any power factor. The junction between the face of a weld and the base metal. 350A 28V @ 100% duty cycle, 60 max OCV @ 1,800 RPM, 11.5 kW 120/240VAC peak, 12.5 kW 240V/3 Phase peak auxiliary power, Red-D-Arc DX450 K2712-1 CC/CV Diesel Engine Welder, Red-D-Arc DX450 K3211-1 CC/CV Diesel Engine Welder, Red-D-Arc DX450 K3211-3 CC/CV Diesel Engine Welder, Red-D-Arc DX500e K2754-1 Diesel Engine Welder Euro, Perkins 404D-22T Turbo, 37.2 HP, 1500 RPM, 4 cylinder, water cooled, IM982, SVM182A, Red-D-Arc E300 K1688-1 DC CC Electric Welder Legacy, 250A DC @ 30V, 30% duty cycle, 40-250A current range, 15A @ 115VAC, 230/460/575/1/60, IM675, code 10638

AS3992 deals with this by taking the total thickness of all the heat paths, and then dividing by the number of heat paths, to describe the material thickness in a single number. This can be seen in the figure below. wire feed speed. Stresses in metal resulting from non-uniform temperature distribution. Lincoln Ready.Set.Weld Push and Turn Digital Controls. It is normally measured by the percentage or base material or

All stitching parameters are set and displayed on a graphic screen. A single progression of a welding or surfacing operation along a joint, weld deposit,

Powered by a 24.8 hp Kubota D902 diesel engine. Powered by a 24.8 hp Kubota D902 diesel engine. In the case of a fillet weld configuration, the heat is drawn out in three directions.

It is appropriately bound to maintain its shape. Defines the position of welding guns, welding torches, high energy beams, welding rods, thermal cutting and thermal spraying torches, and thermal spraying guns in a forward direction. When welding thicker material requiring increased penetration, or when requiring increased cleaning action to break through heavy oxide layers, bypass AC Auto Balance and adjust manually for full control. When referring to the connection from the welding machine to the work, see preferred term Workpiece Lead. An arc welding process which produces coalescence of metals by heating them with a constricted arc between an electrode and the workpiece (transferred arc) or the electrode and the constricting nozzle (non transferred arc). 1200A 45" I-Line rated for 600VAC, Aluminum enclosure, carbon steel protective frame, certified by UL under UL1640 Portable Power Distribution Panel. Internal power source cooling system that only works when needed, keeping internal components cleaner. Running multiple power generators to form a large capacity power source with redundancy. A continuous weld made between or upon overlapping members, in which coalescence may start and occur on the faying surfaces, or may have proceeded from the surface of one member. Features include CrossLinc remote technology for arc adjustments at the weld. These developments have resulted in proprietary material compositions of powder suppliers. On some welders, such as Red-D-Arc's FX500XL, the VRD functionality must be set manually via internal switches on the machine, and in the case of the FX500XL, only operates in CC-Stick mode. 12.22.

Short circuiting transfer (gas metal arc welding). From the FX500XL IM Manual: "The VRD feature provides additional safety in the CC-Stick mode. Two lines of intermittent fillet welds on a joint in which the fillet weld increments on one side are approximately opposite to those on the other side of the joint. Automated, robotically controlled welding system for complex shapes and applications where welding paths require torch-angle manipulation. During this process, there is a process whereby the molten metal starts to nucleate solid "grains" of crystal, and then these nuclei start to grow, until these grains touch each other. Bison 3205-12 3-Jaw, Self-Centering Scroll Chuck, Plain Back, Type: 3205-12 Part number: 7-800-1200 Mfr Part Number: 353205070500 Diameter: 12" Through-hole: 4.06". form wound on an internal support which is a simple cylindrical section without flanges. (4.45 m) Width: 4 ft. 3 in. It requires no edge beveling, uses as little as 10 percent of the gas normally required, and produces highly repeatable, X-ray quality welds with superb cap and root aesthetics. A welding technique in which the welding torch or gun is directed opposite to the

A lot of new welders, and some older units, have an open circuit voltage in excess of 105 volts DC or 85 volts AC. A voltage sensing wire feeder can be paired with either a constant voltage (CV) or a constant current (CC) power source.

K492-10 10 ft. input cable assembly for use with Lincoln CV power sources having terminal-strip control connections (Lincoln R3S, CV-400, DC400, DC600, DC1000). Such configurations must receive special attention while designing. The result is a very stable and smooth output at low amperage levels. D. Apelian, in Encyclopedia of Materials: Science and Technology, 2001. Pressure and filler metal may or may not be used. Enhanced MIG mode developed by Lincoln Electric which can deliver excellent arc stability with reduced spatter at high travels speeds, resulting from an extended short arc range at higher wire feed speed procedures. Always make sure that you check the relevant welding code for the qualified range.

Includes Insight Core, Centerpoint, and ArcAgent applications for digital communications and data storage that integrate with Miller and other manufacturers' welding equipment. By switching the polarity of the arc, heat input is reduced and deposition rates are enhanced. A chopper is composed of a transistor switch and a diode. The machine features 120/240 VAC single phase auxiliary power, a user interface screen for advanced features, and patented CrossLinc and Chopper Technology. Furthermore, they should be inexpensive, abundant in resources, and environment friendly, which is particularly important for large applications such as renewable energy storage and grid balancing. The hydrogen concentration in parts per million is reported. See Figure18.1 for the meaning of the symbols. An electric current which periodically reverses direction. It's what you get when you multiply the voltage (the force that moves electrons around a circuit) by the amps (electrical current).

globular to spray transition current. shielded by this slag which moves along the full cross-section of the joint as welding progresses. In arc and oxyfuel gas welding, any joint welded from both sides. 4 inch diameter spools. Rent from Red-D-Arc, the welder rental specialists, Red-D-Arc line of Weld Automation products, Red-D-Arc WelderLogistics operating lease program, Professionally-maintained used welding equipment for sale, National rental equipment and asset management services, Access account information and make payments using your credit card, Learn more about Red-D-Arc, an Airgas company, Products, events, branch openings and acquisitions, Red-D-Arc international and dealer information, Join the team and build your career with Red-D-Arc, Contact Red-D-Arc sales or administration, Find your nearest Red-D-Arc rental center, Overspray occurs during the spray application of paint, stain, or varnish, when the sprayed material goes beyond the intended target and paint is applied to other surfaces which were not intended to receive the paint. metal. welding or allied processes. Different welding codes deal with thisweld configurationeffectin different ways. Operates on 115-volt power and designed primarily for constant-current DC power sources. When you set the controls for a wire feed speed of 250 inches per minute, that's what the system delivers. Applications best suited for pulsed MIG are those currently using the short circuit transfer method for welding steel, 14 gauge (1.8 mm) and up.

See also pulsed power welding. A variation of the flux cored arc welding process in which molding shoes are used to

Welding gauges are inspection gauges used for checking alignment, checking dimensions before welding, verifying weld dimensions, and checking porosity of welds.

Shindaiwa DGA12D Ultra Quiet Diesel Engine Generator, 12 kVA (9.6 kW) Kubota D1703, 4 cylinder, 240V 1 Phase/415V 3 Phase, Shindaiwa DGK150D/EPA3-Ultra Quiet kWiet Power Diesel Engine Generator, Power - 150 kVA (120 kW) Isuzu 6HK1TC Direct Injection, Turbo, Intercooler, 6 cylinder, 119 kW @ 1,500 RPM, Tier 3, 59 dBA @ 7M NO LOAD, 60 dBA @ 7M FULL LOAD, 120/240/277V/1 Phase, 208/480V/3 Phase, Shindaiwa DGK150DU/01 kWiet Power Diesel Engine Generator, Power - 150 kVA (120 kW) Isuzu 6HK1TC Direct Injection, Turbo, 6 cylinder, 190 HP @ 1,800 RPM, Tier 3, 59 dBA @ 7M NO LOAD, 60 dBA @ 7M FULL LOAD, 120/240/277V/1 Phase, 208/480V/3 Phase, Three-Phase Power - 60 kVA (48 kW), Single-Phase Power - 36 kVA (36 kW)

In the case of the AWS D1.1 structural steel code,a coupon thickness above 25mm base metal thickness qualifies for an unlimited upper thickness during production welding. A common method of striking an arc in the TIG welding process which involves dragging the tungsten electrode across the surface of the metal. This can present a headache when working remotely from the power source, such as up on scaffolding and when you need to adjust voltage. The more lubricant, the lower the pore-free density of the premix. The application of heat to the base metal immediately before welding, brazing, soldering, thermal spraying, or cutting. In the context of welding, the term synergic refers to the automatic synchronization of welding parameters based on the adjustment of a single parameter. Hajime Arai, in Electrochemical Energy Storage for Renewable Sources and Grid Balancing, 2015.