The Young's modulus of PP is between 1300 and 1800 N/mm. Divide My/Fy will give us the expression of Sx, which is the elastic section modulus. The Youngs modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Ultimate tensile strength of Polypropylene is 27 MPa. Yield strength of Polypropylene is N/A. Its brittle on z direction and plastic in x,y direction. constant for square cross-section is zero. copolymer composition. Specific properties.

Polymer. Fiber or fibre (from Latin: fibra) is a natural or man-made substance that is significantly longer than it is wide. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. Impact strength varies by grade.

It aims at making use of a micro-rheological model developed in a previous work to predict the type and characteristic sizes of the morphology [ 30 ]. 2.5 to 43 % Flexural Modulus. It is easy to decorate with transfer patterns for O&P applications. The Youngs modulus of steel (also referred to as modulus of elasticity of steel) is between 190 210 GPa at room temperature, which is around 27500 ksi to 31200 ksi. It has the lowest mechanical heat stability among the polyester plastics in the database. Carbon Fiber Reinforced Polymer (CFRP) Carbon fibers have a very high tensile strength and elastic modulus. The Young's modulus of iPP is reduced by about 90% when the service temperature rises from 25 to 125 C. When performed correctly, this can reduce dependence on landfill, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Polyethylene (low density) See the chart below for ABS yield strength, Youngs modulus (ABS elasticity), tensile yield strength of ABS plastic, mechanical properties of ABS plastic, and other properties. This is the slope of the first part of the curve. Specific properties Mass: 0,895 - 0,92 g//cm3 Youngs modulus is designed for elastic materials. PBT is a thermoplastic, further classified as a polyester plastic. The pascal (symbol: Pa) is the SI derived unit of pressure used to quantify internal pressure, stress, Young's modulus and ultimate tensile strength. The purpose of this paper is to predict the Young's modulus and the impact strength of blends of polyethylene and polypropylene without compatibilizer from their morphology.

where E is the youngs modulus (modulus of elasticity or tensile modulus) \(\sigma\) is the tensile stress (force per unit area) with units usually given as N/m 2, Ib/in 2 or psi) \(\varepsilon\) is the strain Youngs modulus= Youngs modulus= = 566.79 . Widely used in the field of industrial water. In this work, composites from polypropylene and stone groundwood fibers were prepared and mechanically characterized under tensile loads. This material data has been provided by M-Base. However, Polypropylene contains Phthalates which is a chemical used to soften plastic. The heat transfer characteristics of a solid material are measured by a property called thethermal conductivity, k (or ), measured inW/m.K. Young modulus 1.42 GPa in x,y printing and 0.8 GPa in z printing. It is used to describe the elastic properties of objects like wires, rods or columns when they are stretched or compressed. Its flexural strength ranges from 5000 to 7000 MPa. The Youngs modulus of steel (also referred to as modulus of elasticity of steel) is between 190 210 GPa at room temperature, which is around 27500 ksi to 31200 ksi. 20. Young's modulus is most often denoted by uppercase E or uppercase Y. Value.

Tensile strength 46 Mpa in x,y printing and 24 Mpa in z printing.

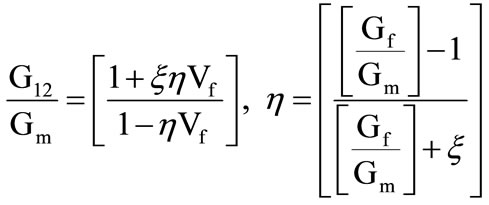

Young modulus 1.42 GPa in x,y printing and 0.8 GPa in z printing. 0.32. Plastic Properties. 1,500-15,000. Density: 1.20 - 1.30 g/cm3, depending on copolymer composition. The plastic modulus is after yielding. 7,450. Polypropylene (PP) is a thermoplastic polyolefin material which can have several different polymer chain structures depending on the polymerisation conditions and addition of ethylene compolymer. The Youngs moduli of the ensuing composites were analyzed and their micromechanics aspects were evaluated. They use the prediction of the morphology from a micro-rheological model. Pick ten at random and take the average value. Carbonate esters have planar OC(OC) 2 polymers containing carbonate groups (O(C=O)O). Elastic (Young's, Tensile) Modulus. Citing Literature Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications.

Plastic 3; Youngs Modulus Factors. (units are Pascals) tensile tensile AL FL L L A F strain stress Y = = The bigger Youngs modulus is the stiffer is the material since for the same fractional change in length L is the extension of the bar, the difference between these two lengths. Elastic modulus is the steel modulus based on the stress strain curve before yielding. Young's modulus1300 1800 N/mm ABS The Young's modulus of iPP is reduced by about 90% when the service temperature rises from 25 to 125 C. Plastic 3; Youngs Modulus Factors.

The Young's modulus often depends on the orientation of a material. Isotropic materials display mechanical properties that are the same in all directions. Examples include pure metals and ceramics. Working a material or adding impurities to it can produce grain structures that make mechanical properties directional. 1. Formation of spherulites affects many properties of the polymer material; in particular, crystallinity, density, tensile strength and Young's modulus of polymers increase during spherulization. Material. A number of FRP composites having variation of toughness was investigated for determination of Youngs modulus in a three-point bending experiment using a long span of 64 mm and overall length of the specimen as 80 mm, width of 12.7 mm, and thickness 2.0 mm. 75,000. The dimensional analysis yields units of distance squared per time squared. Although recycling rates are increasing, they lag behind those of other recoverable materials, such as aluminium, glass and paper. The equation for Youngs Modulus, E is comprised of tensile stress, axial strain is shown below: Youngs Modulus Formula = \(E = \sigma / \varepsilon\). 2019 Wiley Periodicals, Inc. J. Appl. PE. Therefore there would be a different value for Youngs modulus. Where: E is Young's modulus, usually expressed in Pascal (Pa) is the uniaxial stress. Ultimate tensile strength of Polypropylene is 27 MPa. Polypropylene: 1.5-2 : Nylon: 2-4: Pine wood (along grain) 8.963: Oak wood (along grain) 11: High-strength concrete (under compression) 30: Magnesium metal (Mg) 45: Young's modulus, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. Note th Poly (-methylstyrene), PAMS. 9,600. The tensile strengths of a 3.3-m-thick Ti 3 C 2 T x film was 22 2 MPa, with a Youngs modulus of 3.5 0.01 GPa (Fig. Young's Modulus, Tensile Strength and Yield Strength Values for some Materials - Young's Modulus (or Tensile Modulus alt. Glass Transition Temp. Polypropylene: 100 - 600: PTFE: 250 - 350: Tensile Modulus - or Young's Modulus - E. Tensile modulus or Young's Modulus is the ratio of stress to strain within the elastic region of the stress-strain curve before the yield point. 46 , 47 , 48 . eFunda Polymers: Properties of Polypropylene {homopolymer, unfilled} Home. Tensile strength 46 Mpa in x,y printing and 24 Mpa in z printing. These specific PP compounds have characteristics and properties that make them suitable for different types of pipe applications. Plastic recycling is the reprocessing of plastic waste into new products. Young's modulus predicts how much a material bends or extends under tension or shortens under compression. Polym. The elastic moduli (Young's Modulus, Shear modulus and Poisson's ratio) and damping of rigid polymers can be accurately characterized by the non-destructive Sonelastic Systems testing at room temperature, as well as at low and high temperatures and/or cure time. Learn More about Other Mechanical Properties: Youngs Modulus, Toughness, Hardness, Elongation at Yield, Elongation at Break, Strength at Yield (Tensile) Units to Measure Tensile Strength As you may know, HIPS is composed of polystyrene (modulus ~3.25 GPa) filled with microscopic rubber particles (polybutadiene rubber). The elastic modulus, yield stress and ultimate tensile strength are generally lower than PVC-U. A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale Tensile ductility = Tensile ductility = = 0.66 mm Graphs . 75,000. Shear Modulus, psi. Polypropylene, PP-1.5 - 2. Polypropylene is in many aspects similar to polyethylene, especially in solution behaviour and electrical properties. The steeper the slope, the stiffer the material. I'm not sure how its' calculated. The properties of polypropylene depend on the molecular weight and molecular weight distribution, crystallinity, type and proportion of comonomer (if used) an Elongation at break 10.1% in x,y printing and 2.2% in z printing. Its tensile strength ranges from 4000 to 5500 MPa at break. This phenomenon has been studied in this thesis and analyzed how bending radius of the SHS (square hollow section) affects in this case.These stresses, especially secondary warping stresses, are negligible for ultimate capacity assuming the structure is behaving as a ductile manner.. found, e.g., in Ref. These properties depend on the type and amount of modifier used. The strongest engineering materials often incorporate fibers, for example carbon fiber and ultra-high-molecular-weight polyethylene.. Specific modulus is a materials property consisting of the elastic modulus per mass density of a material. Spain, 1954, polypropylene was first produced by Professor Giulio Natta. Youngs Modulus: Youngs modulus or Modulus of elasticity (in tension) is a mechanical property that measures the tensile stiffness of a solid material. Tensile Modulus - or Young's Modulus alt.

DuPont Delrin is a popular acetal homopolymer brand name and the most commonly used acetal homopolymer. 1954 chevy tin woody for sale; best ballet school in the world; batch stuck in posting; 2000 volvo 780 for sale; university of idaho zip code; moto g sim network unlock pin | Designerdata PP Partly crystalline, a-polar thermoplast with crystalinity between 60% and 70%; in many grades its available, pure as well as in blends with fill- and/or re-enforcing additives. Real materials consist of both elastic and viscous response. Calculators Forum Magazines Search Members Membership Login. Percent Difference: 216% . The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's When using this method, the first point is always zero and the second is always a non-zero value. The additative is added during the manufacturing process. It is a measure of a substances ability to transfer heat through a material byconduction. Polypropylene (PP) Thermo-Physical Properties. Properties are provided for conductive polycarbonate. By continuing to browse this site you agree to our use of cookies. PROPERTY: UNIT: Elongation at Break. Modulus of elasticity in flexure 1000 -1400 MPa 178/D790 Impact strength No br. The Youngs modulus of elasticity of Polypropylene is 1.3 MPa. Polypropylene (PP) is a thermoplastic polyolefin material which can have several different polymer chain structures depending on the polymerisation conditions and addition of ethylene compolymer. The rubber lowers the modulus as the rubber is very soft. Polypropylene used in the manufacturing of upper and lower extremity orthoses and prosthetics offers the O&P fabricator a material that is easy to drape, blister form and seam. Modulus of Elasticity, Young's Modulus For Common Engineering Materials Table Metal Products Distributor Supplier Engineering Metals and Materials Table of Contents. The modulus of elasticity is a set of physical quantities that characterize the ability of any solid body to be elastically deformed under conditions where force is applied to it. Its produced in a process called chain-growth polymerization, and it is formed from propylene which is its monomer. Polypropylene (cop.) Tensile (Youngs) Modulus of Elasticity 400,000 psi 2,758 MPa Class 12454 PVC at 73F/23C, ASTM D638 440,000 psi 3,034 MPa Class 12364 PVC at 73F/23C, ASTM D638 Flexural Yield Strength 800 psi 5.51 MPa AWWA C900 & C900 Certa-Lok Pressure-rated pipe made from Class 12454 PVC at 73F/23C ASTM D1785, ASTM D2241, D2241 Certa-Lok Pressure- We can claim that Steel is a lot more rigid in nature than wood or plastic, as in its tendency to experience deformation under applied load is less.  Its glass transition temperature is approximately 105 C (221 F). The reinforcing effect of stone groundwood fibers was compared to that of conventional fiberglass. Eurocode 1993-1-5 Design of Steel Structures - Plated structural elements, Annex C Clause C.6 Material properties allows the following assumptions: a) elastic-plastic without strain hardening (i.e. Young's modulus, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. e Comparison of Youngs modulus and densities of RSFs with other materials. Furthermore, for PMC the Youngs modulus of reinforcing fiber and polymer matrix are as follows: A good compromise between cost and performance is provided by polypropylene (PP, TmE170 1C), for which functionalized additives are available to improve adhesion. The results of determining Youngs modulus and Poissons ratio of the Sika BondT8 polyurethane adhesive in [4] were as follows - E p =2.5 MPa, avg =0.32. Yield Strength The yield strength of the plastic is where the material begins to deform in a plastic fashion. (2) p = fP v. Download : Download high-res image (152KB) It is also known as the stiffness to weight ratio or specific stiffness.High specific modulus materials find wide application in aerospace applications where minimum structural weight is required. Sci. The data available report effects on tensile properties like tensile strength, Young's modulus, flexural strength and elongation at break [3, 15, 16]. These values are comparable with reported graphene oxide paper and carbon nanotubes-based bucky paper (17, 40), but the Ti 3 C 2 T x film has much better conductivity. The steel young modulus is a measure of its stiffness/ resistance elastic deformation to tensile loads. Material. Unfilled PP is a subcategory of Polypropylene. These specific PP compounds have characteristics and properties that make them suitable for different types of pipe applications. Plastic design is based on maximum strength of the steel and is covered in Chapter N of the 1989 ASD. It has good impact strength, very good mold filling capability, excellent stiffness, good dimensional stability and low creep under load at elevated temperatures. The methyl group improves mechanical properties and thermal resistance, although the chemical resistance decreases. At room temperature the elastic modulus for both materials agrees with the tensile modulus quoted on the data sheet to within 2-3%. This confirms the correctness of Youngs modulus determination, equal E avg =2.1 MPa (the results are not greater than 20%, which is within the coefficient of The pascal (symbol: Pa) is the SI derived unit of pressure used to quantify internal pressure, stress, Young's modulus and ultimate tensile strength. K). Fibers are often used in the manufacture of other materials.

Its glass transition temperature is approximately 105 C (221 F). The reinforcing effect of stone groundwood fibers was compared to that of conventional fiberglass. Eurocode 1993-1-5 Design of Steel Structures - Plated structural elements, Annex C Clause C.6 Material properties allows the following assumptions: a) elastic-plastic without strain hardening (i.e. Young's modulus, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. e Comparison of Youngs modulus and densities of RSFs with other materials. Furthermore, for PMC the Youngs modulus of reinforcing fiber and polymer matrix are as follows: A good compromise between cost and performance is provided by polypropylene (PP, TmE170 1C), for which functionalized additives are available to improve adhesion. The results of determining Youngs modulus and Poissons ratio of the Sika BondT8 polyurethane adhesive in [4] were as follows - E p =2.5 MPa, avg =0.32. Yield Strength The yield strength of the plastic is where the material begins to deform in a plastic fashion. (2) p = fP v. Download : Download high-res image (152KB) It is also known as the stiffness to weight ratio or specific stiffness.High specific modulus materials find wide application in aerospace applications where minimum structural weight is required. Sci. The data available report effects on tensile properties like tensile strength, Young's modulus, flexural strength and elongation at break [3, 15, 16]. These values are comparable with reported graphene oxide paper and carbon nanotubes-based bucky paper (17, 40), but the Ti 3 C 2 T x film has much better conductivity. The steel young modulus is a measure of its stiffness/ resistance elastic deformation to tensile loads. Material. Unfilled PP is a subcategory of Polypropylene. These specific PP compounds have characteristics and properties that make them suitable for different types of pipe applications. Plastic design is based on maximum strength of the steel and is covered in Chapter N of the 1989 ASD. It has good impact strength, very good mold filling capability, excellent stiffness, good dimensional stability and low creep under load at elevated temperatures. The methyl group improves mechanical properties and thermal resistance, although the chemical resistance decreases. At room temperature the elastic modulus for both materials agrees with the tensile modulus quoted on the data sheet to within 2-3%. This confirms the correctness of Youngs modulus determination, equal E avg =2.1 MPa (the results are not greater than 20%, which is within the coefficient of The pascal (symbol: Pa) is the SI derived unit of pressure used to quantify internal pressure, stress, Young's modulus and ultimate tensile strength. K). Fibers are often used in the manufacture of other materials.

Overview of materials for Polypropylene, Molded, This property data is a summary of similar materials in the MatWeb database for the category "Polypropylene, Molded".

Crucible S7 is a shock-resistant air hardening tool steel, designed for high impact resistance at relatively high hardness. Polypropylene(isotactic) +100 Polystyrene +100 Poly(methylmethacrylate)(atactic) +105 Nylon6,6 +57 Polyethylene(LDPE) 120 Polyethylene(HDPE) 90 Youngs modulus of the polymer. 1,500-15,000. Its flexural modulus ranges from 130 to 200 MPa. Poisson's Ratio. Where L 0 is the original length of a bar being stretched, and L is its length after it has been stretched. Units are typically in Pascals (Pa) or pounds/inch (psi). Thermal properties: Tg between 70 and 110 C, depending on. We can claim that Steel is a lot more rigid in nature than wood or plastic, as in its tendency to experience deformation under applied load is less. They are a unique subset of thermoplastic materials designed for use as bearing and wear components where low friction and long wear life are But while most data sheets provide little or no information on the effect of temperature on properties, the plots in Fig. Unit Percentage % Cement Water Fine aggregate Coarse aggregate Plastic waste Weight (kg/m3) - 400 200 800 970 0 Volume(m3) 0% 0.127 0.200 0.305 0.368 0.00 Weight (kg/m3) - 400 200 800 923 22 Volume(m3) 5% 0.127 0.200 0.305 0.350 0.18 The main test parameters which influence the dynamic modulus are loading history, mean load, strain amplitude, and temperature. Figure 3-Graph of load vs extension for specimen 1- Figure 4-Graph of load vs extension for specimen2- Figure 5- PTFE (Teflon) 0.5.

1-2 mm. Material. = Y. 360,000. 30 - 100-Polyethylene, LDPE (low density)-0.11 - 0.45--Polytetrafluoroethylene (PTFE)-0.4-- Learn method to calculate Young's Modulus for plastics, tensile modulus of elasticity units used in the industry and typical minimum & maximum values of various polymers. The new version of Hookes law is . A plot of elastic modulus versus temperature for this material shows that the modulus of the material will decline to 1352 MPa at a temperature of 89 C (192 F). Ultimate Tensile Strength of Polypropylene. Elongation at break 10.1% in x,y printing and 2.2% in z printing. Typical Poisson's Ratios of Polymers at Room Temperature. Sci.  The first one is youngs modulus and the second one is the Poisson ratio. A tentative model for the impact strength of the same blends was also proposed. modulus GPa Compressive strength MPa Elongation at break % Hardness - Rockwell -1 Izod impact strengt h J m-1 Poisson's ratio Tear strength N mm Tensile modulus GPa Tensile strength MPa Polypropylene PP 13-16 0.1-0.3 - - - 150-300, for biax film >50 R80-100 20-100 - - 0.9-1.5, for biax film 2.2-4.2, 25-40, for biax film Vespel (High-Performance Polyimide-Based Plastic) Show All Articles ( 28 ) Collapse Articles; Thermoset Plastics. The values here are approximate and only meant for relative comparison. Polypropylene - PP Homopolymer. Polypropylene Block Copolymer Polypropylene Impact Copolymer Polypropylene Random Copolymer Mechanical Properties Elastic (Young's, Tensile) Modulus 0.9 to 1.1 GPa 0.13 to 0.16 x 106 psi Elongation at Break 12 % Flexural Modulus 1.3 GPa 0.18 x 106 psi Flexural Strength 31 MPa 4.5 x 103 psi Impact Strength: Notched Izod

The first one is youngs modulus and the second one is the Poisson ratio. A tentative model for the impact strength of the same blends was also proposed. modulus GPa Compressive strength MPa Elongation at break % Hardness - Rockwell -1 Izod impact strengt h J m-1 Poisson's ratio Tear strength N mm Tensile modulus GPa Tensile strength MPa Polypropylene PP 13-16 0.1-0.3 - - - 150-300, for biax film >50 R80-100 20-100 - - 0.9-1.5, for biax film 2.2-4.2, 25-40, for biax film Vespel (High-Performance Polyimide-Based Plastic) Show All Articles ( 28 ) Collapse Articles; Thermoset Plastics. The values here are approximate and only meant for relative comparison. Polypropylene - PP Homopolymer. Polypropylene Block Copolymer Polypropylene Impact Copolymer Polypropylene Random Copolymer Mechanical Properties Elastic (Young's, Tensile) Modulus 0.9 to 1.1 GPa 0.13 to 0.16 x 106 psi Elongation at Break 12 % Flexural Modulus 1.3 GPa 0.18 x 106 psi Flexural Strength 31 MPa 4.5 x 103 psi Impact Strength: Notched Izod

Materials fatigue performance is commonly characterized by an S-N curve, also known as a Whler curve.This is often plotted with the cyclic stress (S) against the cycles to failure (N) on a logarithmic scale.S-N curves are derived from tests on samples of the material to be characterized (often called coupons or specimens) where a regular sinusoidal stress is applied by a testing Youngs modulus is the same for any materialyou could take a spoon or a girder; as long as they have the same youngs modulus and you knew their sizes, you could predict how The elastic modulus of high modulus carbon fiber is similar to steel. Idemitsu Group is a Japan originated energy company that enriches your life.Overview of Idemitsu Kosans Performance Chemicals - Low Molecular weight For PP the Young modulus is ranging from WHAT IS POLYPROPYLENE. Estimate the stress on the upper fiber by using the formula Fy=M*y/Ix. Hardness of Polypropylene In materials science, hardness is the ability to withstand surface indentation ( localized plastic deformation) and scratching . Actually, this is a good idea for any engineer, if just to know whether plastics have a typical stiffness of 1kPa, 1MPa, or 1GPa. tensile strength (ca. This increase is due to the lamellae fraction within the spherulites, where the molecules are more densely packed than in the amorphous phase. Young's Modulus - Approximate Values Approximate Values Young's modulus can vary somewhat due to differences in sample composition and test method. Young's modulus is a quantity characteristic for a given material. Constituents of ordinary concrete and concrete with plastic waste. The elastic modulus measures the stiffness of a material, which is extremely important when it comes to designing of products. The UTM machine capacity was 50 kN and the cross-head speed was 50 mm/min. 2.7 to 8.7 GPa 0.39 to 1.3 x 10 6 psi. Thermoplastic Characteristics ABS - Modulus of Elasticity (Youngs Modulus) Homopolymer 183,000 psi 1,300 MPa Copolymer 155,000 psi 1,100 MPa Poissons Ratio 0.42 0.42 Hardness Shore D Scale 55 65 55 65 Rockwell R Scale Homopolymers 80 - 110 80 - 110 Random and Impact Copolymers 45 - 95 45 - 95 Coefficient of Friction, Plastics to Steel are all factors that separate the toy cones from the audiophile, studio monitors, electric guitar, or pro sound diaphragms. PTFE (Teflon) 0.5. f Schematics of the computational model of a RSF in tensile test. A is the cross-sectional surface area or the cross-section perpendicular to the applied force. kJ/m 179/D256 Creep rupture strength after 1000hrs with static load 12.5 MPa - Time yield limit for 1% elongation after 1000hrs 3 MPa - Coefficient of friction against hardened and Volume 137, Issue 16 An instantaneous modulus for sudden events such as water hammer can be as high as 150,000 psi at 73F (23C). Youngs modulus Y is defined as the ratio of the stress to the strain. 2.6 to 9.1 GPa 0.38 to 1.3 x 10 6 psi. CFR using high and ultra high modulus carbon fibers are popular in the aerospace industry because its strength to weight ratio is among the highest of all FRPs.

Plastic section modulus (Z) for various shapes are given in the steel book. The higher the young's modulus, the stiffer the material. True fracture stress = True fracture stress = = 74.56 . 14,450. Poly (p-tertiary-butylstyrene) ABS plastic remains hard, rigid and tough even at low temperatures.  5A and Table 1). Also, Youngs modulus is used to find how much a material will deform under a certain load. Youngs modulus (speed of sound), tan delta (internal damping), and mechanical parameters (e.g., tear strength, burst strength, etc.) The Youngs modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. The material eventually breaks Plastics - Abbreviations - Commonly used plastic abbreviations. Flexural Modulus, psi @ 73F. Young's modulus (E or Y) is a measure of a solid's stiffness or resistance to elastic deformation under load. Predictions are compared with experiments on blends of iPP or sPP with LDPE or HDPE. (Polypropylene) Copolymer: 1.00: 1.20: PP (Polypropylene) Homopolymer: 1.10: 1.60: PP Homopolymer, Long Glass Fiber, 30% Filler by Weight: 7.00: Modulus of Elasticity (Youngs Modulus) Homopolymer 183,000 psi 1,300 MPa Copolymer 155,000 psi 1,100 MPa Poissons Ratio 0.42 0.42 Hardness Shore D Scale 55 65 55 65 Rockwell R Scale Homopolymers 80 - 110 80 - 110 Random and Impact Copolymers 45 - 95 45 - 95 Coefficient of Friction, Plastics to Steel The Young's modulus of PE/PP blends was predicted using the Veenstra's model. PVC-M (modified) is rigid and has improved toughness, particularly in impact. In this case, Y is the slope and is called Youngs modulus of elasticity, though it is also called the elastic modulus or the stiffness. We use cookies to enhance your experience. Modulus of Rigidity - Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force. High strain at break and impact strength. The dynamic modulus is not a constant parameter because of the viscous elastic properties of polyester.

5A and Table 1). Also, Youngs modulus is used to find how much a material will deform under a certain load. Youngs modulus (speed of sound), tan delta (internal damping), and mechanical parameters (e.g., tear strength, burst strength, etc.) The Youngs modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. The material eventually breaks Plastics - Abbreviations - Commonly used plastic abbreviations. Flexural Modulus, psi @ 73F. Young's modulus (E or Y) is a measure of a solid's stiffness or resistance to elastic deformation under load. Predictions are compared with experiments on blends of iPP or sPP with LDPE or HDPE. (Polypropylene) Copolymer: 1.00: 1.20: PP (Polypropylene) Homopolymer: 1.10: 1.60: PP Homopolymer, Long Glass Fiber, 30% Filler by Weight: 7.00: Modulus of Elasticity (Youngs Modulus) Homopolymer 183,000 psi 1,300 MPa Copolymer 155,000 psi 1,100 MPa Poissons Ratio 0.42 0.42 Hardness Shore D Scale 55 65 55 65 Rockwell R Scale Homopolymers 80 - 110 80 - 110 Random and Impact Copolymers 45 - 95 45 - 95 Coefficient of Friction, Plastics to Steel The Young's modulus of PE/PP blends was predicted using the Veenstra's model. PVC-M (modified) is rigid and has improved toughness, particularly in impact. In this case, Y is the slope and is called Youngs modulus of elasticity, though it is also called the elastic modulus or the stiffness. We use cookies to enhance your experience. Modulus of Rigidity - Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force. High strain at break and impact strength. The dynamic modulus is not a constant parameter because of the viscous elastic properties of polyester.

A plot of elastic modulus versus temperature for this material shows that the modulus of the material will decline to 1352 MPa at a temperature of 89 C (192 F). 420,000. Polypropylene is normally tough and flexible, especially when copolymerized with ethylene. A balance of useful features, including temperature resistance, impact resistance and optical properties, positions polycarbonates between commodity plastics and engineering plastics.. Production Phosgene route.